Non-magnetic zone

If you place a suspended (overband) magnet, keep the following in mind:

When positioning the magnet, the construction below the magnet such as the frame, bearing rollers and reversing rollers must be made of non-magnetic material. This is because steel parts will become magnetized, which will adversely affect the separation performance of the overband magnet.

Goudsmit uses the following rule of thumb:

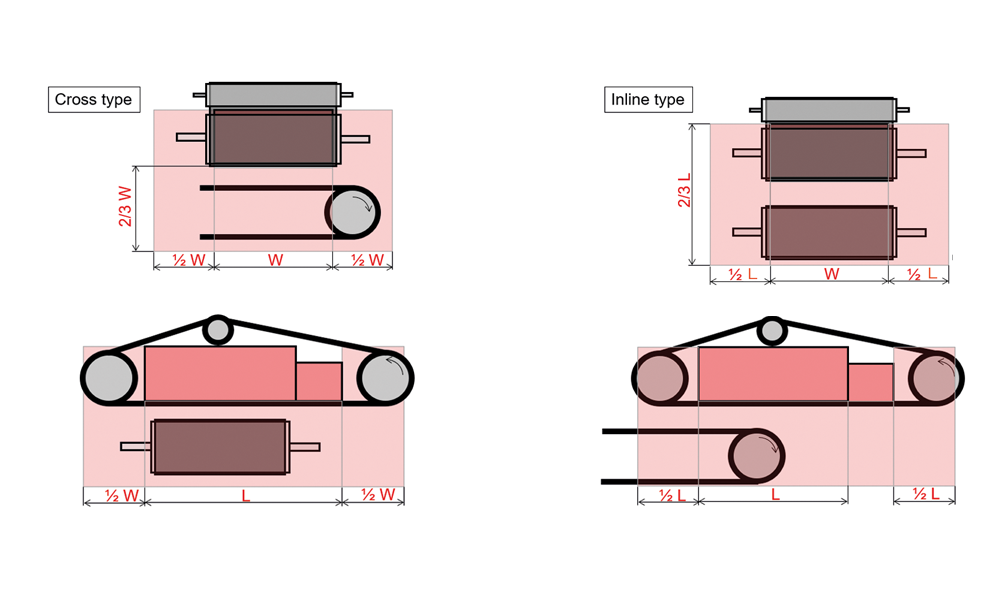

Keep the area extending a distance of 1/2 of the magnet’s width (shown below as 'W' or ‘L’) on all sides free of magnetic material. For the area below the magnet, maintain a non-magnetic zone of 2/3W or 2/3L. It is important to make all components in this zone out of stainless steel, plastic or other non-magnetic material.